Media

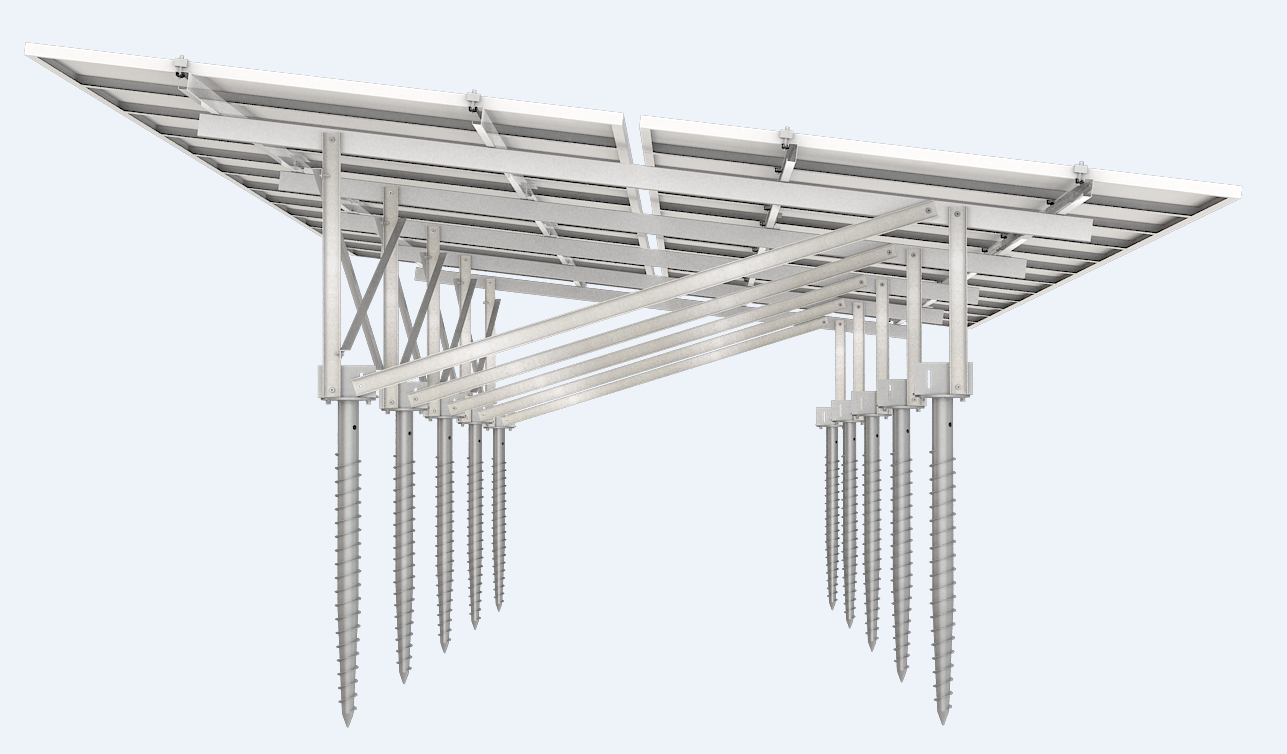

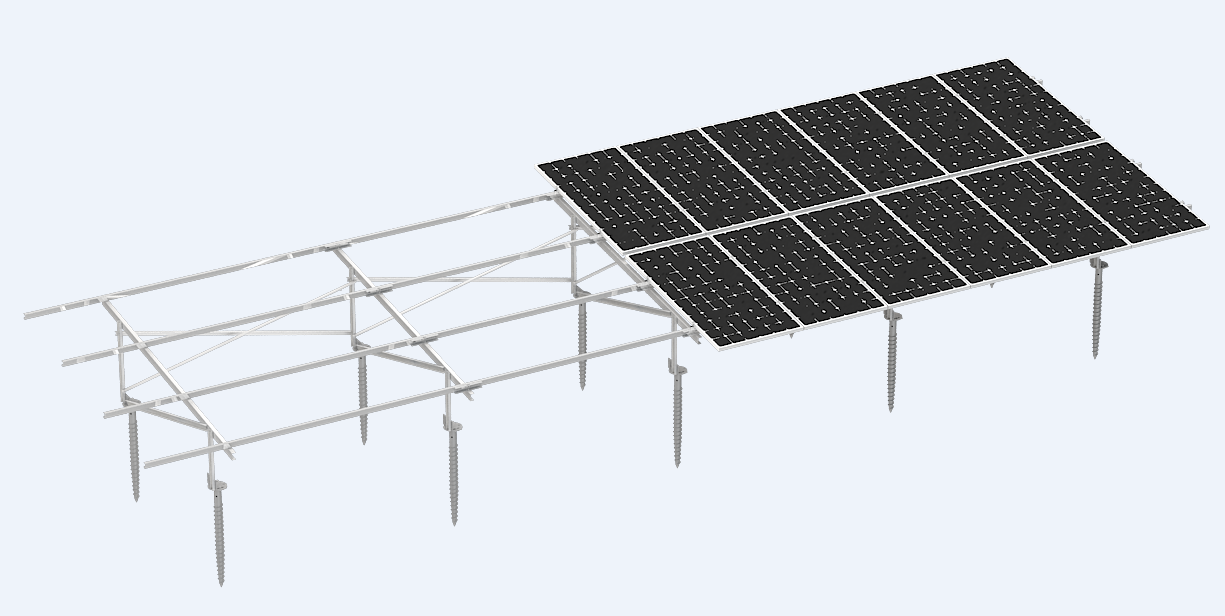

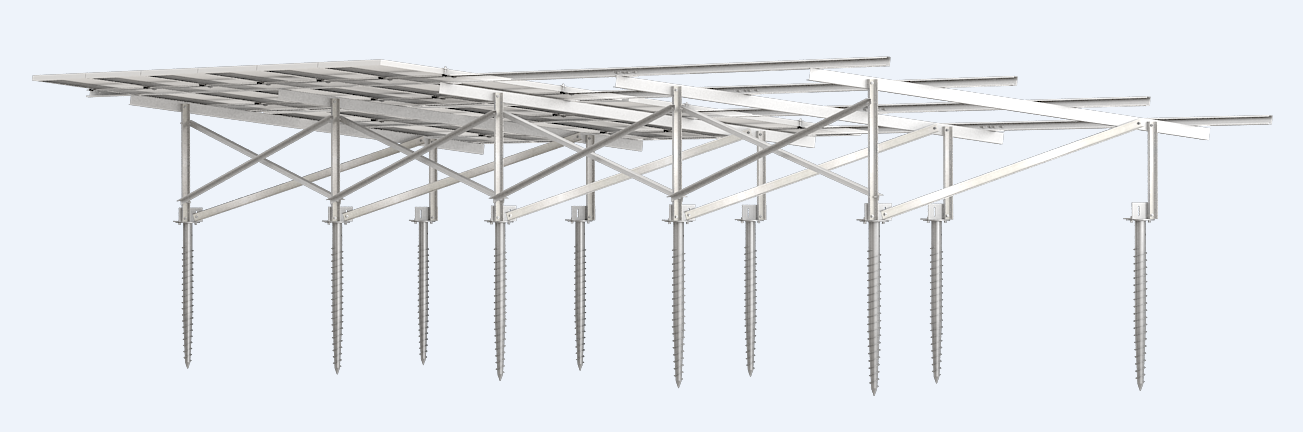

Zn-Mg-Al Ground Mounting Structure

As an important "skeleton" part for building and supporting PV power systems, the robustness and corrosion resistance of mounting structures are particularly important. Engomy Zn-Mg-Al Ground Mounting Structure is made of materials with Al, Mg, Ni, Cr and other alloy coatings integrated into the based on Zn coating, . Compared with traditional hot-dip galvanized steel, its corrosion resistance and damage resistance are greatly improved, which helps to extend the service life of the structures. Zn-Mg-Al coated materials are widely used in cable trays, greenhouses, railway roads, automobile motors, cooling towers, industrial air-conditioning and other fields; and now it’s applied in the PV mounting structures, with very significant advantages than HDG steel..

—— Applications of Zn-Mg-Al Ground Mounting Structures ——

Due to excellent corrosion resistance and damage resistance of Zn-Mg-Al coated steel, it has a wide range of applications:

Areas with high-corrosive soils, coastal areas with high salinity

Severe industrial atmospheric environments, agriculture/greenhouses, carports, and fisheries

—— Features of Zn-Mg-Al Ground Mounting Structures ——

01 Strong damage resistance:With low friction coefficient and stable friction characteristics, Zn-Mg-Al coated material can reduce the wear of coating; During transportation or installation, it can effectively reduce the damage and consumption of the structure itself and ensure the integrity of the mounting system.

02 Super corrosion resistance:Engomy Zn-Mg-Al ground mounting systems are made of steel alloys integrated with zinc-magnesium-aluminum elements in the coating, which greatly improves the corrosion inhibition effect of the coating. Compared with traditional hot-dip galvanized steel, its corrosion resistance is increased by 5-10 times, with life span up to 30 years.

03 Strong self-repair:For either damaged coating or processing cuts, the coating material nearby will dissolve into the water film attached to the bare metal surface, and continuously migrate and infiltrate to the exposed incision positions to form a dense protective film (white rust), which gradually covers the incisions, and separate external corrosive media from exposed metal and thus to prevent further corrosion.

04 Cost-effective:Due to its high corrosion resistance, damage resistance and self-repairing property, Zn-Mg-Al mounting structures will have extended service life, no need of regular maintenance after completion of the construction, which effectively reduces the operating cost of the power station. Moreover, the pee-assembly of mounting products makes easy installation thus helps to save installation time and labor cost..

闽公网安备 35020602000236号

闽公网安备 35020602000236号